Reverse Engineering

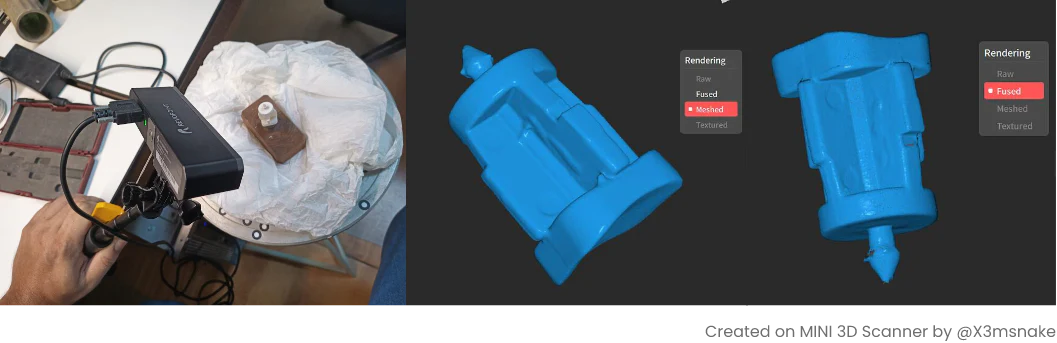

Reverse engineering is the process of taking something and deconstructing it, studying its structure, learning how it works, and how it was made to understand its design. This is often a painstaking days-long process of manually measuring everything, drawing diagrams, and double-checking that the information is correct. Fortunately, now, it can be done much faster with the help of Revopoint 3D scanners. They enable accurate 3D models to be created quickly and imported into CAD software for transformation into a working manufacturing model in only a few hours.

Legacy Equipment

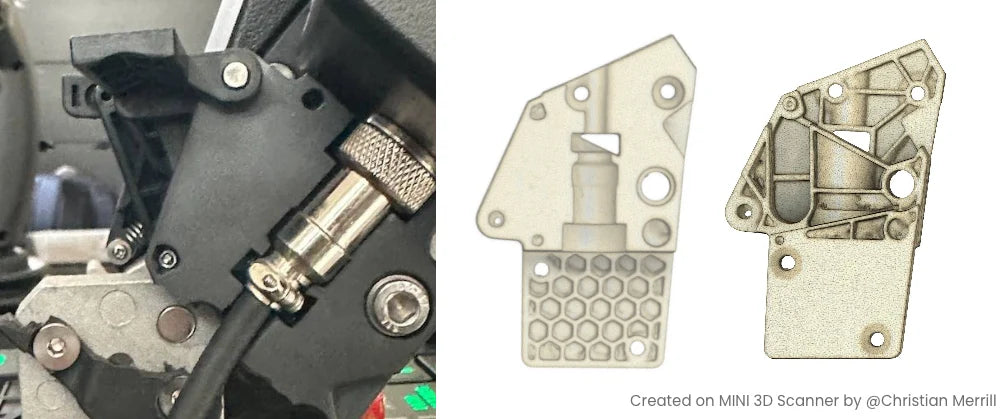

Finding replacement parts for old equipment or infrastructure can be challenging, and having it out of action for weeks waiting around for measurements and prototypes isn’t an option either. However, with a Revopoint 3D scanner, machine parts can be scanned and reproduced quickly.

Modifying Equipment

Streamline product modification using a Revopoint 3D scanner. Scanning the object and creating a digital representation allows you to analyze and make necessary modifications to enhance its design or functionality.

Product Development Research

Understanding how your competitors make their products is invaluable in helping drive forward product design, and by using a Revopoint 3D scanner, you can uncover the design intent behind a product. Scanning the object and creating a digital model allows you to analyze the intricate details and dimensions, enabling a deeper understanding of the original design.

Recommended Products

MIRACO 3D SCANNER

Up to 0.02 mm Precision, 0.05 mm accuracy

For Scanning: Small to Large Objects All-in-one Scanning