3D scanners and 3D printers are like peas in a pod when it comes to creating limitless possibilities and turning imagination into reality. Whether you’re an artist, engineer, or hobbyist, this dynamic duo will take your project to a new level. And as you should know by now, we’ve certainly got the 3D scanners covered for you, but what are your options for different types of 3D printers?

Fused Deposition Modeling (FDM)

FDM 3D printers are the most commonly used type of 3D printer on the market as they are cost-effective and perhaps the easiest way to 3D print. They work by melting a plastic filament and then extruding it layer by layer onto a build plate to print the item. Not only are FDM printers very affordable, but the filament is also, without contest, the cheapest 3D printing material, around $15 to $30 per kilo. However, it’s worth remembering that particularly cheap filament might not provide a good print.

There are, however, some downsides to FDM printing, as they can require a lot of adjustments, fiddling, and maintenance of parts to get decent prints consistently. Also, they aren’t great at printing items with fine details because extruders can only really get as small as 0.2 mm, so finer details won’t come out particularly well.

And depending on what kind of thing you’re printing, it may require a lot of support struts added to the model for a successful print, and these can take a while to remove when done, and some prints need a good amount of post-processing to make the final item look good.

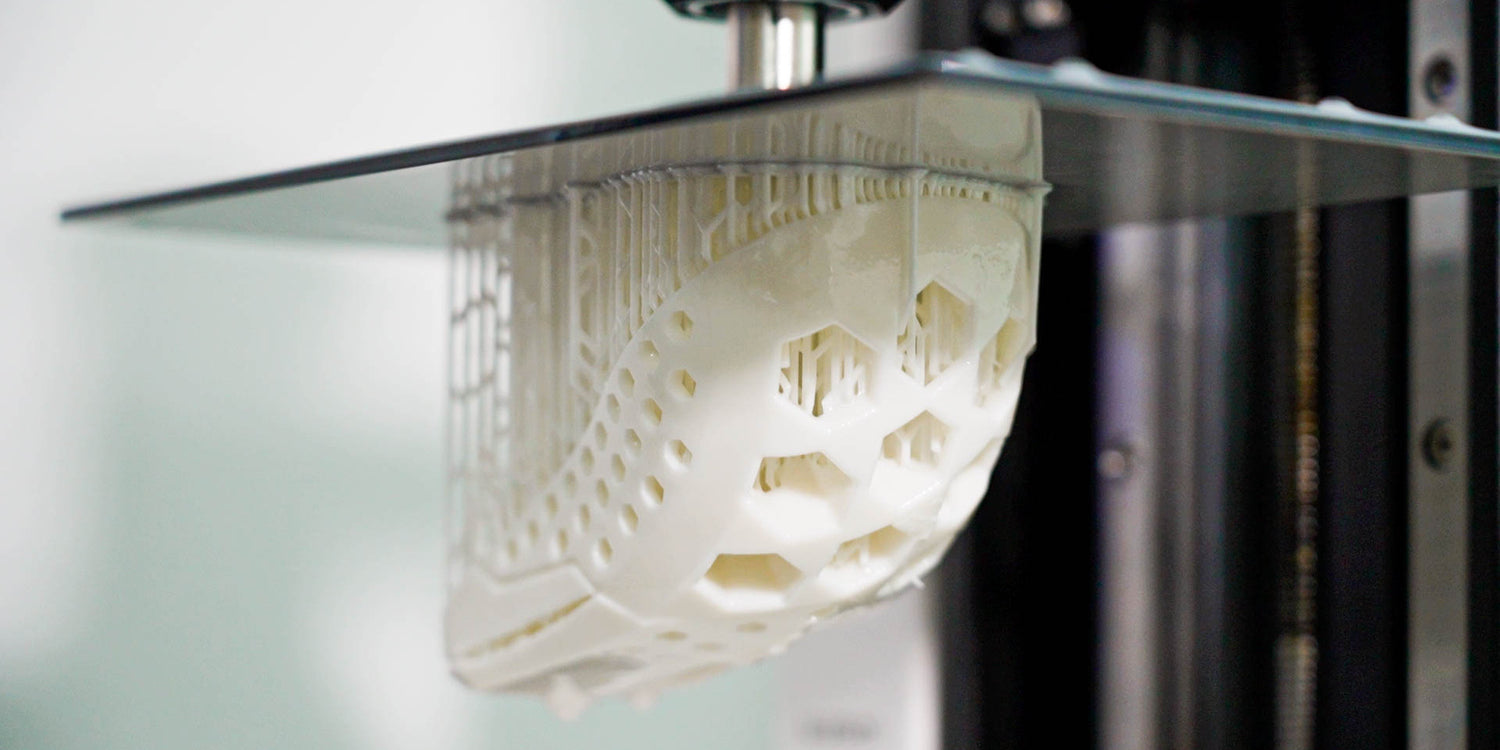

Stereolithography (SLA)

These are the most common resin 3D printers and are pretty popular in the 3D printing scene, but not as popular as FDM printers. They use a UV light source that cures light-reactive liquid resin layer by layer to print the desired item. 3D prints from SLA printers tend to be accurate and have really smooth surfaces. SLA printers can be gotten for a couple of hundred dollars all the way up into the thousands of dollars.

However, good quality resin can be expensive, over $150 a kilo. And after the print has finished, the model usually needs to be dipped into a bath of isopropyl alcohol (IPA) to move any excess resin before finally curing the model under a UV lamp to strengthen the print. Resin also smells bad and ideally shouldn’t be used in poorly ventilated environments. And like FDM printers, SLA printers also require support structures to be attached to the model before printing. So while SLA printers can provide very good prints, they are more labor-intensive than FDM printers.

Selective Laser Sintering (SLS)

SLS 3D printers also produce prints in plastic but at a more industrial level than an FDM or SLA printer. SLS can create highly detailed, strong, and durable parts. This kind of 3D printing uses nylon-based powders being hit with a laser to form a strong plastic. SLSs used to be pretty expensive, with units costing hundreds of thousands of dollars, but recently some manufacturers have lowered the costs to slightly under ten thousand dollars. Though, these cheaper units will, of course, still pale in comparison to their more expensive counterparts.

Digital Light Process (DLP)

DLP is quite similar to SLA but quite a bit faster because it cures entire layers at once with its light rather than part by part, like an SLA and its UV laser. While they can produce parts with intricate designs with accuracy, they don’t provide robust prints. And as it uses resin, it’ll create an unpleasant chemical odor, and the prints’ lack of strength means larger models have a higher risk of warping. DLPs are generally more expensive than SLAs, starting at around $2,000.

PolyJet

This method is like an inkjet printer in the way it works by placing droplets of a photopolymer onto the build plate. The UV light passes over the layer to solidify it. The main advantage of this kind of 3D printer is that it’s speedy, accurate, can do detailed color prints, and produce parts using multiple different materials. A neat little innovation is that supporting structures made with a PolyJet can be washed away with water, making it faster to finish the model after printing.

While PolyJets are MJFs cheaper cousin, they can still run fairly expensive at over $20,000, and the resin isn’t cheap either, with a kilogram potentially costing hundreds of dollars.

Multi Jet Fusion (MJF)

MJFs are becoming increasingly popular in the manufacturing industry for their speed, low cost per part, and ability to print in color. Like the Polyjet, MJF uses multiple inkjet heads to place its binding agent on the nylon powders to form the print before it’s heat treated with an infrared heating unit to finish. However, MJFs are not cheap and can easily run over $50,000 in setup costs.

Direct Metal Laser Sintering (DMLS)

As its name suggests, DMLS 3D prints metal parts. They are popular in the aerospace, medical, and automotive industries for their ability to produce high-precision strong metal parts for prototyping or to be directly used in a machine or vehicle.

DMLS uses a high-power laser to fuse metal powders layer-by-layer to create the object. You can use many different types of metal powder depending on your requirements. And the ability to create metal parts up to a meter in size without tooling is a significant time saver. Unsurprisingly, DMLS printers are expensive, often costing hundreds of thousands of dollars, and are rather costly to run with their power-hungry lasers and expensive metal powders.

Electron Beam Melting (EBM)

EBM is another 3D printer that can produce metal objects. It works by blasting metal powder with an electron beam that melts the powder to form the object’s shape as it prints. The prints are dense and strong enough to be used in machines. EBMs are faster and slightly cheaper than DMLS printers but require a skilled operator to take advantage of one and can only print items about half the size of the ones DMLS can manage.

One last thing before we finish, it’s never a good idea to leave a 3D printer running unattended for long periods, as it can be a fire hazard.

Now you know all about the different types of 3D printers, why not learn more about 3D scanners?

How 3D Scanning and Rapid Prototyping are Changing the Game

5 Reasons to Get a 3D Scanner

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.